Home » Application » 5 Functions of Variable Frequency Drive in Motor

5 Functions of Variable Frequency Drive in Motor

When talking about variable frequency drive, we firstly think of speed regulation, what else functions do it have? What is the first function or application coming in mind when mentioning the VFD? Next this paper would introduce five functions of VFD:

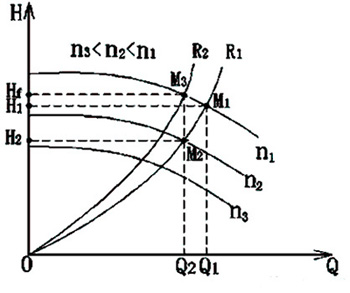

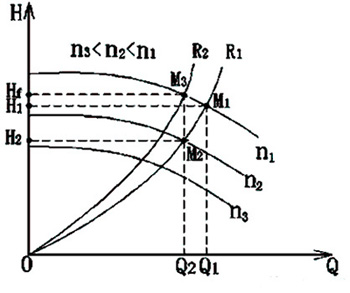

Frequency Conversion and Energy Saving

The most prominent application of VFD frequency conversion and energy saving is in the fan and water pump industries. Power consumption of fan and pump is proportional to the cube of rotational speed, so when the consumption of air/ water is not high, VFD can be used to slow down the rotation speed, the energy-saving effect would be significant. The principles of energy saving in other industries are probably the same, namely energy saving is achieved by lowering motor speed without full speed operation.

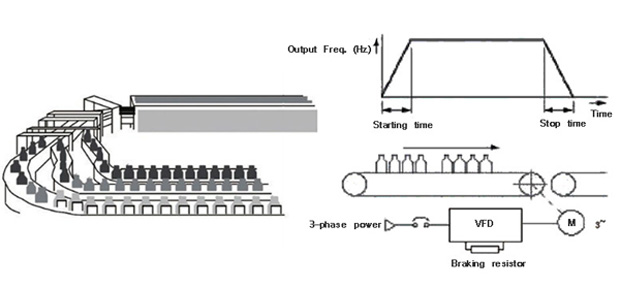

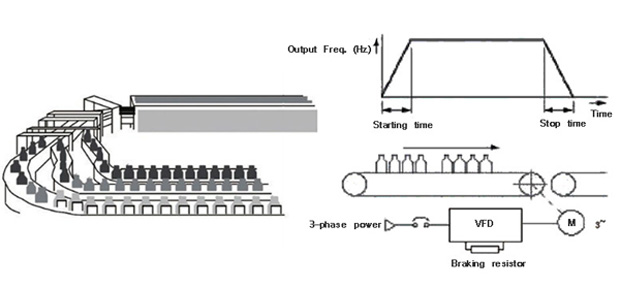

Soft Start

When the motor is started directly under power frequency, it will generate a current which is 7 to 8 times of the rated current. This current will greatly increase the electrical stress of the motor winding and generate heat, thus reducing the service life of the motor. It will also have a great impact on the power grid. However, VFD can be started at zero speed and zero voltage (torque also can be properly increased). Once the relationship between frequency and voltage is established, the VFD can drive the load according to V/F or vector control mode. Application of VFD can fully reduce the starting current, improve the bearing capacity of winding, reduce the impact of starting current on motor and power grid, and prolong the service life of motor. Meanwhile, it will not cause excessive difference between peak and valley value, or fault tripping or abnormal operation of voltage sensitive equipment in power supply network.

Simplification of Control System

VFD can start at zero speed and accelerate uniformly according to user’s needs, moreover, its acceleration curves are also selective (linear acceleration, S-shaped acceleration or automatic acceleration). The running speed can be adjusted at any time according to the need and can be changed rapidly according to the process, it can also realize speed change by remote control PLC or other controllers.

Reduce Mechanical Wear and Loss

Serious vibration would be caused on to the motor or connected mechanical part or gear when starting under the power frequency, such a vibration will further aggravate mechanical wear and loss, and reduce the service life of mechanical components and motors. In the variable frequency drive, stop mode can be controlled and different stop modes can be selected (deceleration stop, free stop, deceleration stop + DC braking). It can reduce the impact on mechanical components and motors, so that the whole system is more reliable. Meanwhile, service life of the system will be increased accordingly, and the stability of the system will be improved.

Adjustable Torque Limit

After VFD frequency conversion, corresponding torque limit can be set to protect the machinery from damage, so as to ensure the continuity of the process and the reliability of products. The current frequency conversion technology not only makes the torque limit adjustable, but also controls the torque accuracy to be about 3%~5%. In power frequency state, the motor can only be controlled by detecting the current value or thermal protection, but can not be operated by setting a precise torque value as in the frequency conversion control.

With the development of science, VFD will be more and more extensively used, and its role will be further increased. It can be used on whether the industrial equipment or domestic appliance, and VFD will play a greater role as electric energy converter.

Frequency Conversion and Energy Saving

The most prominent application of VFD frequency conversion and energy saving is in the fan and water pump industries. Power consumption of fan and pump is proportional to the cube of rotational speed, so when the consumption of air/ water is not high, VFD can be used to slow down the rotation speed, the energy-saving effect would be significant. The principles of energy saving in other industries are probably the same, namely energy saving is achieved by lowering motor speed without full speed operation.

Soft Start

When the motor is started directly under power frequency, it will generate a current which is 7 to 8 times of the rated current. This current will greatly increase the electrical stress of the motor winding and generate heat, thus reducing the service life of the motor. It will also have a great impact on the power grid. However, VFD can be started at zero speed and zero voltage (torque also can be properly increased). Once the relationship between frequency and voltage is established, the VFD can drive the load according to V/F or vector control mode. Application of VFD can fully reduce the starting current, improve the bearing capacity of winding, reduce the impact of starting current on motor and power grid, and prolong the service life of motor. Meanwhile, it will not cause excessive difference between peak and valley value, or fault tripping or abnormal operation of voltage sensitive equipment in power supply network.

Simplification of Control System

VFD can start at zero speed and accelerate uniformly according to user’s needs, moreover, its acceleration curves are also selective (linear acceleration, S-shaped acceleration or automatic acceleration). The running speed can be adjusted at any time according to the need and can be changed rapidly according to the process, it can also realize speed change by remote control PLC or other controllers.

Reduce Mechanical Wear and Loss

Serious vibration would be caused on to the motor or connected mechanical part or gear when starting under the power frequency, such a vibration will further aggravate mechanical wear and loss, and reduce the service life of mechanical components and motors. In the variable frequency drive, stop mode can be controlled and different stop modes can be selected (deceleration stop, free stop, deceleration stop + DC braking). It can reduce the impact on mechanical components and motors, so that the whole system is more reliable. Meanwhile, service life of the system will be increased accordingly, and the stability of the system will be improved.

Adjustable Torque Limit

After VFD frequency conversion, corresponding torque limit can be set to protect the machinery from damage, so as to ensure the continuity of the process and the reliability of products. The current frequency conversion technology not only makes the torque limit adjustable, but also controls the torque accuracy to be about 3%~5%. In power frequency state, the motor can only be controlled by detecting the current value or thermal protection, but can not be operated by setting a precise torque value as in the frequency conversion control.

With the development of science, VFD will be more and more extensively used, and its role will be further increased. It can be used on whether the industrial equipment or domestic appliance, and VFD will play a greater role as electric energy converter.

Post a Comment:

You may also like:

Variable Frequency Drives

Featured Articles

Variable Frequency Drive for Food ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...Variable Frequency Drive for Fans

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...