Home » Application » Variable Frequency Drive for Fans

Variable Frequency Drive for Fans

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ventilator. Conversely, it plays a role of blower. Both ventilators and blowers are called fans. From the perspective of application, the fan can be divided into quadratic fan and constant torque fan.

Main parameters of fan

Air pressure: air pressure per unit area in a pipeline is called air pressure, which is represented as PF with the unit of Pa.

Air flow: namely the air flow rate, it refers to the total amount of gas discharged per unit time, it’s represented as QF with the unit of M3/S.

There are two ways to adjust the air flow:

According to the theory of gas dynamics, the gas flow rate is proportional to the rotation speed of fan, the torque is proportional to the square of rotation speed, and the shaft power is proportional to the cube of rotation speed. When the rotation speed decreases, the output power of motor will decrease in cubic order. When the required air flow keeps the same, less power would be consumed by adjusting the rotation speed, namely its energy-saving effect is more obvious.

Problems existing in the operation of current fan system:

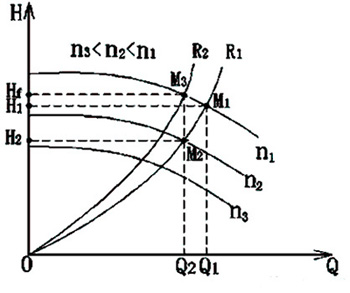

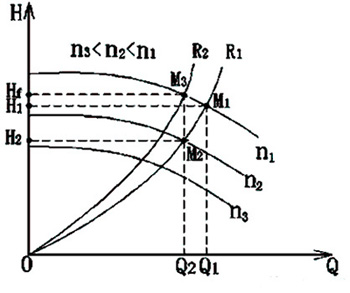

Adjust the air flow by changing the fan’s rotation speed and pipe characteristics. When adjusting a same air flow, characteristic curve (H-Q curve) of the fan changes differently, operation conditions of the two adjustment methods are also different. Comparisons are as follows:

Comparisons of characteristic curve under rotation speed adjustment and damper adjustment.

Effect of fans after energy-saving modification with variable frequency drive

1. Save a lot of energy, the power saving rate in actual application is about 15%~55%.

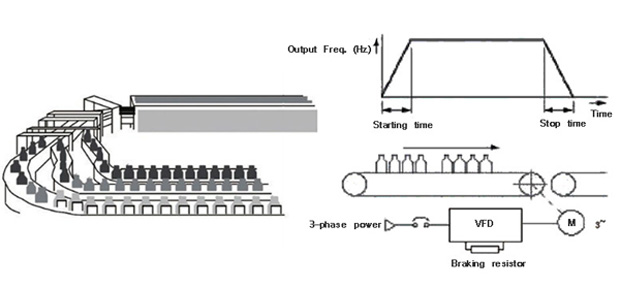

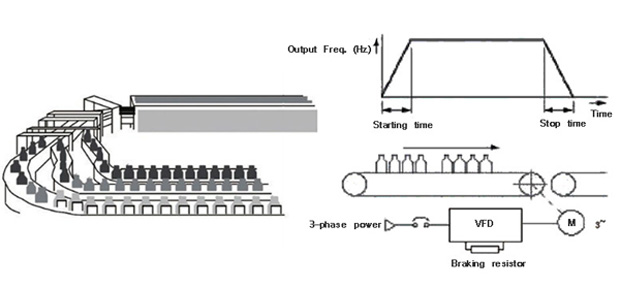

2. Soft-start energy saving, reduce current impact in motor start-up

Due to direct starting or Y/D starting, starting current of the motor is (4-7) times of the rated current, which may have a serious impact on electromechanical equipment and power supply grid. Moreover, it will also have higher requirements to the power grid capacity. The large current and vibration produced during start-up cause great damage to the baffle, and is detrimental to the service life of equipment and pipelines.

After using the variable frequency drives, the soft-start function of variable frequency drive enables the starting current to change from 0. Observing the load curve of VFD during starting, it can be found that there’s no impact at starting, the current changes from 0 and increases with the increase of rotation speed. However, the maximum value would never exceed the rated current. Therefore, variable frequency operation of the fan extends the service life of motor and switches, avoids the impact of starting current and starting torque to the motor, and extends the service life of motor, saves the maintenance cost of equipment.

3. Power factor compensation energy saving

Reactive power not only increases line loss and heating of equipment, more importantly, reduction of power factor leads to the reduction of reactive power in power grid, a large amount of reactive power is consumed in the circuit, the equipment efficiency is quite low. According to the formula P=S*COSФ, Q=S*SINФ (among, S refers to the apparent power, P refers to the active power, Q refers to the reactive power, COSФ refers to power factor), we know that the larger COSФ is, the larger the active power P is. Power factors of common fans are generally between 0.7-0.85. After using the VFD, due to the effect of internal filter capacitor in the VFD, COSФ≈1, the reactive power loss is reduced, active power of power grid is increased.

4. Reduce equipment wear

After using the VFD, rotation speed of the motor generally works at 25~45Hz, the motor’s rotation speed is low, thus reducing the wear of fan blades and bearings, extending the service life and reducing the maintenance cost. The failure rate decreases and faults such as mechanical wear, stuck of baffle disappear, which minimizes the impact of shutdown and stoppage on production.

5. Noise reduction

VFD not only reduces the fan’s operation speed, but also reduces the noise greatly. Meanwhile, it also overcomes the defects in pipeline caused by poor linearity of adjustment damper and poor adjustment quality, such as pipeline resonance, system pipeline whistles, the operation conditions are improved.

6. Realize the automatic control of unit

In the past, when the unit load changes, it can be only adjusted by damper adjustment, which is difficult to control. VFD is equipped with computer interfaces and has open-loop and closed-loop control functions, it can be easily connected to the system and realize the automatic control of unit. VFD can adjust directly by increasing or decreasing frequency, but also conduct automatic closed loop adjustment by inputting analog quantity on external component, so it operates simply and flexibly.

Main parameters of fan

Air pressure: air pressure per unit area in a pipeline is called air pressure, which is represented as PF with the unit of Pa.

Air flow: namely the air flow rate, it refers to the total amount of gas discharged per unit time, it’s represented as QF with the unit of M3/S.

There are two ways to adjust the air flow:

- Adjust the opening degree of the air throttle. While the rotation speed keeps constant, the wind pressure characteristics will also remain unchanged. Wind resistance characteristics change along with the opening degree of air throttle. The power consumed by the fan is proportional to the product of wind pressure and air flow, so the power consumption reduces slightly as the air flow reduces by adjusting the air throttle.

-

Adjust the rotation speed. While the opening degree of air throttle keeps unchanged, the wind pressure characteristics will also remain unchanged. The wind pressure characteristics change along with the rotation speed. As the fan follows a quadratic law load, the power consumed is proportional to the cube of rotation speed.

According to the theory of gas dynamics, the gas flow rate is proportional to the rotation speed of fan, the torque is proportional to the square of rotation speed, and the shaft power is proportional to the cube of rotation speed. When the rotation speed decreases, the output power of motor will decrease in cubic order. When the required air flow keeps the same, less power would be consumed by adjusting the rotation speed, namely its energy-saving effect is more obvious.

Problems existing in the operation of current fan system:

- Current fans mostly use traditional damper adjustment to control air flow, and there’s a huge pressure loss in the air duct. Based on the installation position of damper in the air duct, it can be divided into outlet damper control and inlet damper control. In the outlet damper control, when the damper is turned down, the wind resistance increases, it can’t adjust the air flow extensively. The inlet damper control controls a wider range of air flow than the outlet damper control, when turning down the inlet damper, the shaft power decreases in proportion to air flow. Damper adjustment is a kind of adjustment mode with poor economic benefit, high energy consumption and difficult maintenance.

- Ventilator in many equipment keeps a margin, or runs at a medium and low air flow in most times according to process characteristics.

- When the unit load changes, adjustment can only be realized through adjusting the damper, which is difficult to control.

- Damper adjustment has a poor adjustment linearity and quality, meanwhile, frequent damper adjustment operation leads to the decrease of reliability for damper adjustment.

-

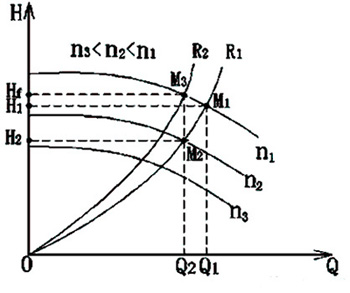

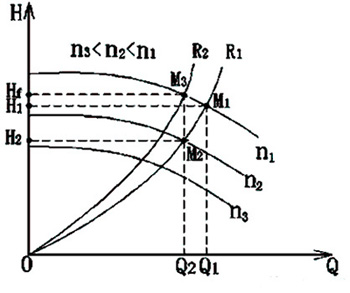

The fan motor doesn’t match well, a lot of electric energy is wasted. For the same type of fan, the H-Q curve at different rotation speed is shown in the below figure according to the proportionality law of fan parameters.

Adjust the air flow by changing the fan’s rotation speed and pipe characteristics. When adjusting a same air flow, characteristic curve (H-Q curve) of the fan changes differently, operation conditions of the two adjustment methods are also different. Comparisons are as follows:

Comparisons of characteristic curve under rotation speed adjustment and damper adjustment.

Effect of fans after energy-saving modification with variable frequency drive

1. Save a lot of energy, the power saving rate in actual application is about 15%~55%.

2. Soft-start energy saving, reduce current impact in motor start-up

Due to direct starting or Y/D starting, starting current of the motor is (4-7) times of the rated current, which may have a serious impact on electromechanical equipment and power supply grid. Moreover, it will also have higher requirements to the power grid capacity. The large current and vibration produced during start-up cause great damage to the baffle, and is detrimental to the service life of equipment and pipelines.

3. Power factor compensation energy saving

Reactive power not only increases line loss and heating of equipment, more importantly, reduction of power factor leads to the reduction of reactive power in power grid, a large amount of reactive power is consumed in the circuit, the equipment efficiency is quite low. According to the formula P=S*COSФ, Q=S*SINФ (among, S refers to the apparent power, P refers to the active power, Q refers to the reactive power, COSФ refers to power factor), we know that the larger COSФ is, the larger the active power P is. Power factors of common fans are generally between 0.7-0.85. After using the VFD, due to the effect of internal filter capacitor in the VFD, COSФ≈1, the reactive power loss is reduced, active power of power grid is increased.

4. Reduce equipment wear

After using the VFD, rotation speed of the motor generally works at 25~45Hz, the motor’s rotation speed is low, thus reducing the wear of fan blades and bearings, extending the service life and reducing the maintenance cost. The failure rate decreases and faults such as mechanical wear, stuck of baffle disappear, which minimizes the impact of shutdown and stoppage on production.

5. Noise reduction

VFD not only reduces the fan’s operation speed, but also reduces the noise greatly. Meanwhile, it also overcomes the defects in pipeline caused by poor linearity of adjustment damper and poor adjustment quality, such as pipeline resonance, system pipeline whistles, the operation conditions are improved.

6. Realize the automatic control of unit

In the past, when the unit load changes, it can be only adjusted by damper adjustment, which is difficult to control. VFD is equipped with computer interfaces and has open-loop and closed-loop control functions, it can be easily connected to the system and realize the automatic control of unit. VFD can adjust directly by increasing or decreasing frequency, but also conduct automatic closed loop adjustment by inputting analog quantity on external component, so it operates simply and flexibly.

Post a Comment:

You may also like:

Variable Frequency Drives

Featured Articles

Variable Frequency Drive for Food ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...Variable Frequency Drive for Fans

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...