Home » Application » Variable Frequency Drive for Food Conveyor

Variable Frequency Drive for Food Conveyor

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the overall equipment level of food machinery to a certain extent. Effects of VFD is mainly reflected on the following two aspects: increasing the output and reducing cost. It can improve production technology, improve product output and quality, thus saving cost effectively.

It can realize software of control and ensure non-tripping operation through torque compensation, stall prevention and reclosing function.

How to choose the appropriate VFDs to meet the increasing modernization demand of food conveyor has been a difficulty for all the food machinery manufacturers. The appropriate VFD shall be able to meet the environment of food production, meet the variation of food related load and close to the user’s psychological needs. And the GK3000 series VFDs provided by ATO is an ideal OEM product.

Application of VFD in Food Conveyor

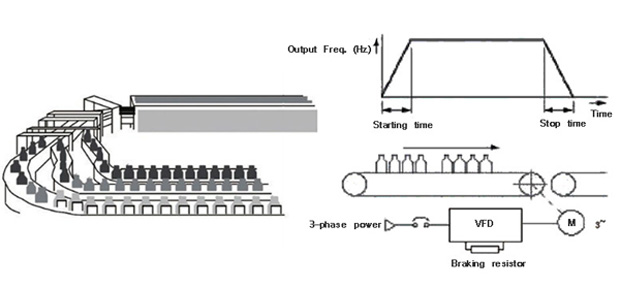

VFDs are widely used in the food conveyor, for example, material shall be conveyed by transmission belt before the cake is baked and pass the baking chamber uniformly according to the baking process. Two transmission equipment are used in this process (material conveyor belt and baking line conveyor belt), and the speed of two equipment shall match, so as to facilitate the raise and falling at a same time. In the past, speed regulation of such equipment was completed by manual mechanical stepped transmission (such as changing the size of belt pulley or the gear ratio of gear box), but now the range of speed regulation can be extended with variable frequency drive, stepless speed regulation can also be realized.

Production line of bottled drinks. In the transmission system, users can control the transmission speed of conveyor belt according to the size and quality of raw material, so as to ensure uniform texture. Meanwhile, users can also achieve speed synchronization and slight adjustment functions according to the speed ratio requirements between different transmission systems. Because different working conditions require different speed sources to control the drive components of transmission system, VFD shall have sufficient frequency sources and operation modes. ATO three phase VFD has three running command channels (operation panel given, control terminal given and serial communication given) and can switch between different modes. It contains 10 frequency sources (numerical given, analog voltage given, analog current given, pulse given, serial port given etc ) and 10 auxiliary frequency sources, so it can switch flexibly and realize the slight adjustment of auxiliary frequency and frequency integration. Variable frequency drive is used in the transmission drive control of bottled drinks production line, and the following effects would be achieved through the VFD:

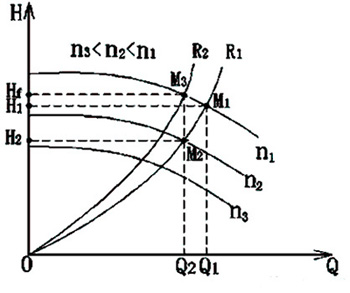

1. Great increase in output: In the vector control mode of speed sensorless (SVC), the control range of VFD is 1:100, control accuracy is ±0.5%. For different food process technologies, VFD can easily control the main speed of food conveyor while other transmission devices will automatically synchronize matching without need of manual adjustment.

2. Give full play to the advantages of asynchronous motor: When regulating speed with VFD, there’s no need to install additional mechanical speed regulating mechanism, the transmission system would be more compact and lighter, the gear asynchronous motor could also operate more efficiently. As the actuator of transmission system is merely the motor without additional mechanical components, only by improving the protection level of motor can apply it in the wet environment, outdoor or riot situation. Similarly, variable frequency speed regulation avoids frequent maintenance work of replacing carbon brush or commutator in speed regulation of DC motor. Of course, variable frequency speed regulation is also simple and effective for some asynchronous motor transmission systems operating at constant speed, only adding the VFD can complete modification.

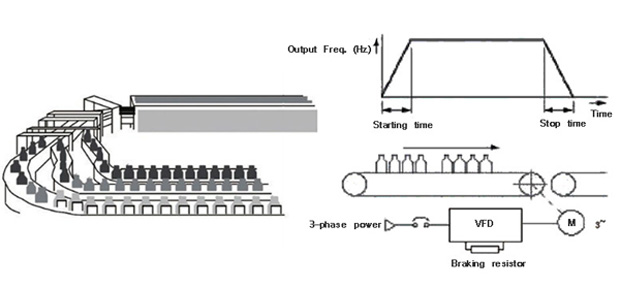

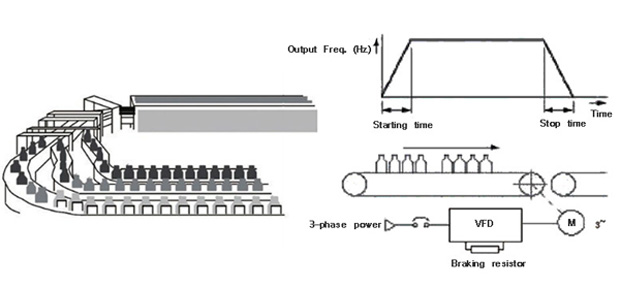

3. Soft start and soft stop functions: In a transmission system, full-speed start-up can cause damage to objects, such as the bottled drinks production line in the figure. With variable frequency drive, it’s easy to start at zero speed and full load. ATO VFD provides 150% starting torque at 0.5Hz under the SVC control mode, so it can start smoothly while overcoming the starting friction torque. Meanwhile, VFD can also provide soft stop function when stopping. The figure (right) shows the frequency/time curve of VFD, whose acceleration time and deceleration time can be adjusted in 0-3000s. The acceleration and deceleration curves can be divided into straight line and S-shaped curve with 4 kind of acceleration and deceleration time built in (select through terminal).

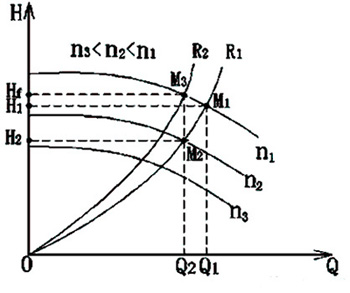

4. Complete operation functions: Functions of starting, stopping, point movement (forward or reverse) and reverse operation can be easily realized by terminal lead and terminal parameter group. The forward and reverse functions of motor require different contactor under power frequency, but VFD completes the functions only by changing the output phase sequence. Braking is a common function of frequency conversion operation. In the figure, VFD is connected with a braking resistor to realize quick braking, so as to treat the regenerative energy in braking process.

5. Running beyond rated speed: VFD allows the motor to run between 0Hz to the maximum output frequency. As soon as the motor is not overloaded when running beyond rated speed, it can runs normally.

6. Improve conveying accuracy: for example, after using the variable frequency drive, the powdery material conveying system can proportionally control the conveying speed of powdered raw materials or it’s easy to realize the uniform loading of powder materials on conveyor belts, thus improving the feeding accuracy.

It can realize software of control and ensure non-tripping operation through torque compensation, stall prevention and reclosing function.

How to choose the appropriate VFDs to meet the increasing modernization demand of food conveyor has been a difficulty for all the food machinery manufacturers. The appropriate VFD shall be able to meet the environment of food production, meet the variation of food related load and close to the user’s psychological needs. And the GK3000 series VFDs provided by ATO is an ideal OEM product.

Application of VFD in Food Conveyor

VFDs are widely used in the food conveyor, for example, material shall be conveyed by transmission belt before the cake is baked and pass the baking chamber uniformly according to the baking process. Two transmission equipment are used in this process (material conveyor belt and baking line conveyor belt), and the speed of two equipment shall match, so as to facilitate the raise and falling at a same time. In the past, speed regulation of such equipment was completed by manual mechanical stepped transmission (such as changing the size of belt pulley or the gear ratio of gear box), but now the range of speed regulation can be extended with variable frequency drive, stepless speed regulation can also be realized.

1. Great increase in output: In the vector control mode of speed sensorless (SVC), the control range of VFD is 1:100, control accuracy is ±0.5%. For different food process technologies, VFD can easily control the main speed of food conveyor while other transmission devices will automatically synchronize matching without need of manual adjustment.

2. Give full play to the advantages of asynchronous motor: When regulating speed with VFD, there’s no need to install additional mechanical speed regulating mechanism, the transmission system would be more compact and lighter, the gear asynchronous motor could also operate more efficiently. As the actuator of transmission system is merely the motor without additional mechanical components, only by improving the protection level of motor can apply it in the wet environment, outdoor or riot situation. Similarly, variable frequency speed regulation avoids frequent maintenance work of replacing carbon brush or commutator in speed regulation of DC motor. Of course, variable frequency speed regulation is also simple and effective for some asynchronous motor transmission systems operating at constant speed, only adding the VFD can complete modification.

3. Soft start and soft stop functions: In a transmission system, full-speed start-up can cause damage to objects, such as the bottled drinks production line in the figure. With variable frequency drive, it’s easy to start at zero speed and full load. ATO VFD provides 150% starting torque at 0.5Hz under the SVC control mode, so it can start smoothly while overcoming the starting friction torque. Meanwhile, VFD can also provide soft stop function when stopping. The figure (right) shows the frequency/time curve of VFD, whose acceleration time and deceleration time can be adjusted in 0-3000s. The acceleration and deceleration curves can be divided into straight line and S-shaped curve with 4 kind of acceleration and deceleration time built in (select through terminal).

4. Complete operation functions: Functions of starting, stopping, point movement (forward or reverse) and reverse operation can be easily realized by terminal lead and terminal parameter group. The forward and reverse functions of motor require different contactor under power frequency, but VFD completes the functions only by changing the output phase sequence. Braking is a common function of frequency conversion operation. In the figure, VFD is connected with a braking resistor to realize quick braking, so as to treat the regenerative energy in braking process.

5. Running beyond rated speed: VFD allows the motor to run between 0Hz to the maximum output frequency. As soon as the motor is not overloaded when running beyond rated speed, it can runs normally.

6. Improve conveying accuracy: for example, after using the variable frequency drive, the powdery material conveying system can proportionally control the conveying speed of powdered raw materials or it’s easy to realize the uniform loading of powder materials on conveyor belts, thus improving the feeding accuracy.

Post a Comment:

You may also like:

Variable Frequency Drives

Featured Articles

Variable Frequency Drive for Fans

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...Variable Frequency Drive for Food ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...