Home » Application » Variable Frequency Drive for Packaging Machine

Variable Frequency Drive for Packaging Machine

I. Variable frequency drive control principle of main drive of packaging machine

1. Characteristics of main drive

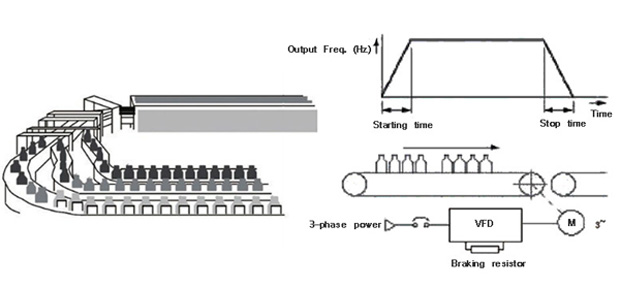

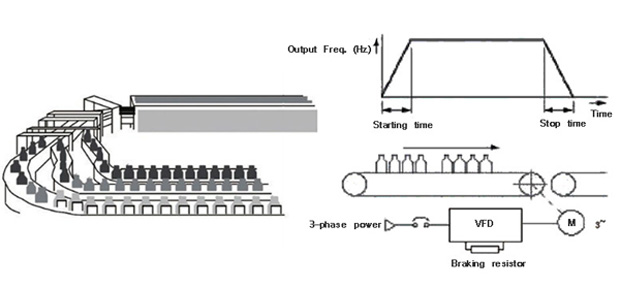

Main drive and conveying system is an important part of the filling-sealing packaging machine, it controls the production speed and material convey. Generally, the main drive and conveying system is powered by an active steering wheel, others are mechanically synchronized through gears, synchronous belts or other mechanical means. Figure below shows the main drive of filling-sealing packaging machine.

The filling-sealing packaging machine often has two requirements to the main drive:

As the best speed regulation and control equipment at present, VFD is the first choice for the main drive controller of filling-sealing packaging machine. It realizes stepless speed regulation by changing the frequency of power supply of asynchronous motor.

After using the variable frequency drive control, main driving motor shaft of the filling-sealing packaging machine is directly connected with load, and the motor is supplied power by VFD, so as to realize the stepless speed regulation in a wide frequency range, such as 0~650Hz. VFD of the filling-sealing packaging machine would adopt one of the three control modes in operation, including V/f control mode, vector control mode and direct torque control (DTC).

II. Frequency given mode of VFD to filling-sealing packaging machine

The purpose of using VFD in the filling-sealing packaging machine is to change the rotation speed of motor by changing the output frequency of VFD, namely changing the power supply frequency of motor driven by VFD. But how to regulate the output frequency of VFD?

The key is to provide frequency-changing signals to VFD first, and this signal is called frequency given signal. The so-called frequency given mode refers to the specific method of regulating VFD input frequency, namely the method to provide given signals.

Common frequency given methods in VFD mainly include: keyboard given, contact signal given, analog signal given, pulse signal given and communication mode given. These frequencies given modes have their advantages and disadvantages respectively, they have to be selected and set by actual needs. Different given modes can also be overlapped and switched according to function needs.

III. Operation instruction mode of filling-sealing packaging machine VFD

Operation instruction mode of VFD means how to control the basic operation functions of VFD, which include the starting, stopping, forward and reverse point movement, reset. Similar to the frequency given mode of VFD, its operation instruction mode also has three modes of keyboard control, terminal control and communication control. These operation instruction modes have to be selected and set by actual needs. Meanwhile, different modes can also be switched according to function needs.

1. Characteristics of main drive

Main drive and conveying system is an important part of the filling-sealing packaging machine, it controls the production speed and material convey. Generally, the main drive and conveying system is powered by an active steering wheel, others are mechanically synchronized through gears, synchronous belts or other mechanical means. Figure below shows the main drive of filling-sealing packaging machine.

The filling-sealing packaging machine often has two requirements to the main drive:

- Wide range of speed regulation. To ensure the technological requirements of sealing packaging, the main drive shall be operated at a low speed when the filling-sealing packaging machine is starting. After the machine is normally started, it shall run at a high speed to meet a necessary production efficiency.

-

High dynamic performance. The system requires a fast dynamic following performance and high steady speed accuracy, so as to ensure the sealing and packaging quality.

As the best speed regulation and control equipment at present, VFD is the first choice for the main drive controller of filling-sealing packaging machine. It realizes stepless speed regulation by changing the frequency of power supply of asynchronous motor.

After using the variable frequency drive control, main driving motor shaft of the filling-sealing packaging machine is directly connected with load, and the motor is supplied power by VFD, so as to realize the stepless speed regulation in a wide frequency range, such as 0~650Hz. VFD of the filling-sealing packaging machine would adopt one of the three control modes in operation, including V/f control mode, vector control mode and direct torque control (DTC).

II. Frequency given mode of VFD to filling-sealing packaging machine

The purpose of using VFD in the filling-sealing packaging machine is to change the rotation speed of motor by changing the output frequency of VFD, namely changing the power supply frequency of motor driven by VFD. But how to regulate the output frequency of VFD?

The key is to provide frequency-changing signals to VFD first, and this signal is called frequency given signal. The so-called frequency given mode refers to the specific method of regulating VFD input frequency, namely the method to provide given signals.

Common frequency given methods in VFD mainly include: keyboard given, contact signal given, analog signal given, pulse signal given and communication mode given. These frequencies given modes have their advantages and disadvantages respectively, they have to be selected and set by actual needs. Different given modes can also be overlapped and switched according to function needs.

III. Operation instruction mode of filling-sealing packaging machine VFD

Operation instruction mode of VFD means how to control the basic operation functions of VFD, which include the starting, stopping, forward and reverse point movement, reset. Similar to the frequency given mode of VFD, its operation instruction mode also has three modes of keyboard control, terminal control and communication control. These operation instruction modes have to be selected and set by actual needs. Meanwhile, different modes can also be switched according to function needs.

Post a Comment:

You may also like:

Variable Frequency Drives

Featured Articles

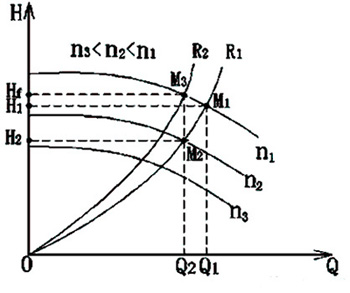

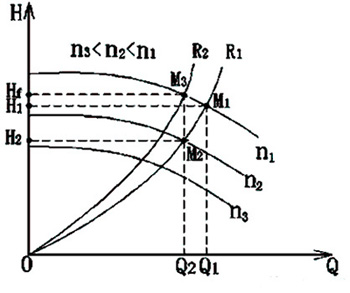

Variable Frequency Drive for Fans

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...

Fan is a kind of machine that compresses and conveys gas. If the pressure of exhausted air is quite low, the fan plays a role of ...Variable Frequency Drive for Food ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...

Nowadays the food machinery industry has been rapidly developed. As the motor drive, variable frequency drive will change the ...